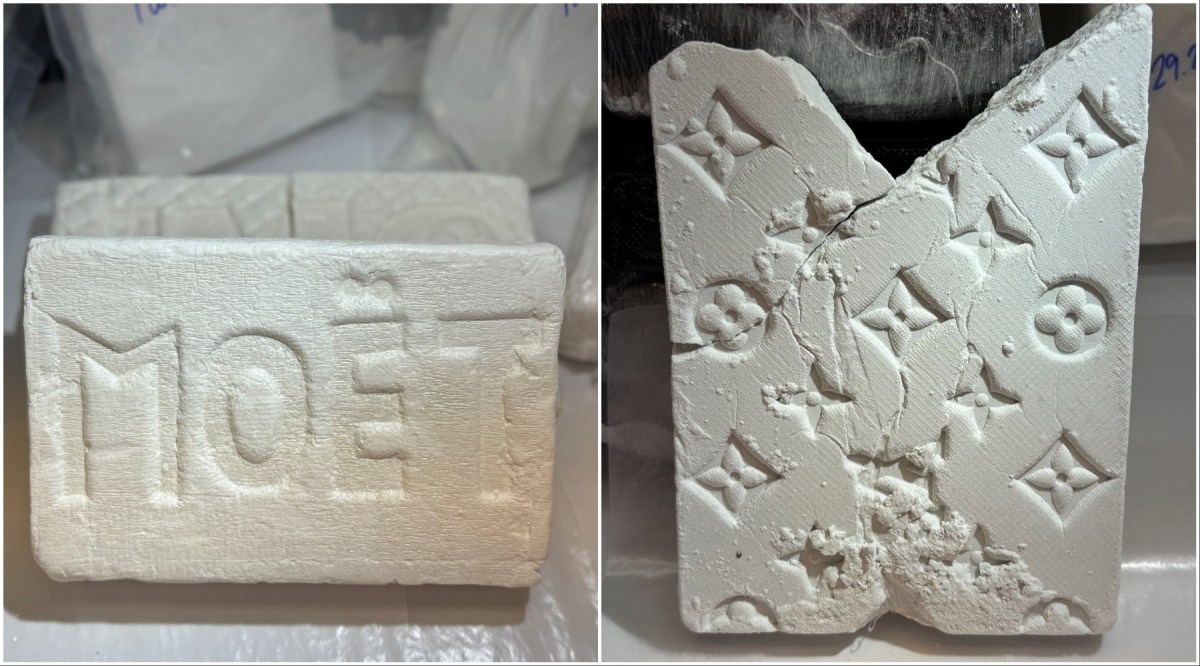

BY GREG BEATO | Last May, Cody Wilson produced an ingeniously brief but nuanced manifesto about individual liberty in the age of the ever-encroaching techno-state — a single shot fired by a plastic pistol fabricated on a leased 3D printer.

While Wilson dubbed his gun The Liberator, his interests and concerns are broader than merely protecting the Second Amendment. Wilson is ultimately aiming for the “transcendence of the state,” as he has said. And yet because of the nature of his invention, many observers reacted to his message as reductively as can be: “OMG, guns!”

Local legislators were especially prone to this response. In California, New York and Washington, D.C., officials all floated proposals to regulate 3D-printed guns. In Philadelphia, the City Council successfully passed a measure prohibiting their unlicensed manufacture, with a maximum fine of $2,000.

But if armies of Davids really want to transcend the state, there are even stronger weapons at their disposal: toothbrush holders, wall vases, bottle openers, shower caddies and tape dispensers. All these consumer goods and more you either can or will soon be able to produce using 3D printers.

Imagine what will happen when millions of people start using the tools that produced The Liberator to make, copy, swap, barter, buy and sell all the quotidian stuff with which they furnish their lives. Rest in peace, Bed Bath & Beyond. Thanks for all the stuff, Foxconn, but we get our gadgets from Pirate Bay and MEGA now.

Once the retail and manufacturing carnage starts to scale, the government carnage will soon follow. How can it not, when only old people pay sales tax, fewer citizens obtain their incomes from traditional, easy-to-tax jobs, and large corporate taxpayers start folding like daily newspapers? Without big business, big government can’t function.

3D printing is a painstaking process, with extruders or lasers methodically building up objects one layer at a time. Most consumer-level devices currently only print in plastic, and only in one color. At online platforms such as Thingiverse.com — where 3D printing enthusiasts share open-source design files and post photos of their wares — the final products often look a little rough around the edges, without the spectacular gloss and streamlining we’ve come to expect from, say, a Dollar General toilet bowl scrubber.

In many ways, 3D printing barely seems ready to disrupt the monochromatic knickknacks industry, much less the world. When it takes hours to produce a pencil cup, transcending the state may prove to be a tall order.

And yet in the industrial realm, where 3D printing has been around for decades and goes by the name “additive manufacturing,” companies such as Boeing and General Electric are using much more sophisticated machines to produce parts for jet engines. Medical device companies use them to custom-manufacture hearing aids, replacement knees and designer prosthetics. In time, Cornell University professor Hod Lipson predicts in the 2013 book “Fabricated: The New World of 3D Printing” (Wiley), 3D printers will be capable of constructing houses with plumbing and wiring in place, and printing “vanity organs” for people who want new or improved athletic abilities.

Inevitably, such technologies and capabilities will trickle down, and probably faster and more radically than many people anticipate. While MakerBot Replicators may still look a little too DIY for those of us who have yet to fully exploit the capacities of our microwave ovens, ease of use is evolving rapidly.

In January, Adobe announced that it is adding 3D printing capabilities to Photoshop, giving users the ability to design three-dimensional objects and send them to their own printers or 3D printers in the cloud. A California startup called AIO Robotics is developing a machine that points the way toward a future where the goods in the picture-frame aisle at Target become just as easy to duplicate and manipulate as Metallica’s back catalog. It’s called Zeus. It looks like an unusually stylish kitchen appliance, and its creators, who met as students at the University of Southern California, describe it as the “world’s first 3D copy machine.”

Place an object in its central chamber, then push a button. Zeus scans the object in 3D. Push another button, and Zeus uses the 3D file it has created to reproduce an exact plastic replica of your object. In essence, Zeus makes “making” even easier than consuming. If you decide you really, really like the pasta bowl your mom gave you for Christmas, you don’t even have to go to the mall, or surf Amazon.com to get another. Just throw it in Zeus and push a button!

In almost all visions of the 3D-printed future, manufacturing changes dramatically. If a high-end 3D printer can fabricate a pistol or a panini press on demand, why bother with huge production runs, global distribution networks, warehoused inventories and the cheap human labor that only under-regulated developing nations can provide? While it will still make sense to produce some goods in large quantities using traditional methods, manufacturing is poised to become a far more local, just-in-time, customized endeavor.

But if the nature of manufacturing is poised to change dramatically, what about the nature of consumption? In many ways, it’s even harder to imagine a city of, say, 50,000 without big-box retailers than it is to imagine it without a daily newspaper. So perhaps 3D printing won’t alter our old habits that substantially. We’ll demand locally made kitchen mops, but we’ll still get them at Target. We’ll acquire a taste for craft automobile tires, but we’ll obtain them from some third party that specializes in their production. Commercial transactions will still occur.

But if history is any guide, more and more of us will soon be engaging in all sorts of other behaviors, too. Making our own goods. Sharing, swapping and engaging in peer-to-peer commerce. Appropriating the ideas and designs of others and applying them to our own ends. Combining resources and collaborating on extremely large and ambitious projects we couldn’t hope to accomplish alone. And, over time, these new behaviors will have consequential impacts on scores of products, companies and industries.

Already, according to a study authored by Joshua Pearce, a Michigan Technological University engineering professor, and six others, there are significant economic incentives for consumers to pursue 3D printing. According to Pearce’s calculations, a person who constructs an open-source 3D printer called the RepRap, at a cost of around $575 for parts, can theoretically avoid paying between $290 and $1,920 a year to retailers simply by using the device to print 20 common items (iPhone case, shower curtain rings, shoe orthotics, etc.).

If you are willing to invest some time in its construction — Pearce estimates that the RepRap takes around 24 hours to build — the printer can quickly pay for itself, even if you don’t use it all that often. If you start making orthotics for your neighbors, who knows? It could even turn into a profit center.

Soon, we’ll begin to see the rise of manufacturing Matt Drudges and printer-sharing Reddits. So many different producers will be churning out so many different products that it will become harder and harder for even well-established and trusted brands to charge for anything but the scarcest and most coveted goods. In a bid to survive, places like Walmart and Best Buy will begin to offer stuff as a subscription — you’ll get 200 pounds of goods per year for a monthly fee of $19.99.

But maybe even that will seem too steep to you, or just not as autonomous as you’d like. Ultimately, 3D printers and the distributed manufacturing they enable will democratize and mainstream survivalism. You won’t need five remote acres, heavy equipment and a lot of practical know-how to live off the grid.

Be prepared, however, to expect some pushback from your local regulators. Consumers must be protected against strawberry balsamic jam made in home kitchens. Travelers must be protected from cheap rides from the airport.

When government realizes that self-produced plastic shower curtain rings are far more potentially disruptive than self-produced plastic pistols, it’ll be more than libertarian entrepreneur-iconoclasts at risk.

Greg Beato is a contributing editor at Reason magazine.